End-to-End High/Low voltage Design | Quality | Scaled Manufacturing

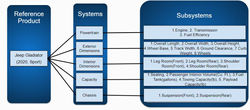

A Vehicle Development Program for Model Year (MY) 2025 Jeep Gladiator

September 2019 - December 2019

Overview

This project involves, developing a robust vehicle program for the Model Year 2025 from the Cradle to the Grave to present a business plan to the panel of directors for approval. The program must take into account any estimate fluctuations in the market, recessions, setup costs, labour, change in emission norms and technology. The program vehicle should be best in class and designed to dominate the market in its category/segment.

Benchmarking and market study of competitor vehicles

Benchmarking was conducted comparing specifications of the Jeep Gladiator 2020 and its competitors to come up with a class leading design for the 2025 Model year. The market was studied thoroughly for demographics on segment classifications. Homologation of curb weight, gross weight based on NHTSA and FMVSS standards was affirmed. Target customer demographics was compiled. From the data collected design improvements and challenges where identified.

|  |  |

|---|---|---|

|  |  |

|  |  |

|

Benchmarking table

You can access the benchmarking table here.

QFD, Requirements Cascade and Interface Analysis for Front Suspension System

Due to the vast level of systems and subsystems interaction in an automobile, performing analysis and cascading requirements on all of them would be a daunting task for a group of four. Hence for the scope of this project only the front suspension system was selected.

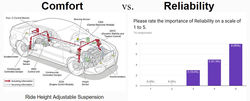

The system was decomposed to the components level using a decomposition tree. The interactions between the front suspension system, subsystems, and other vehicle systems was established using a border diagram/interface diagram. Quality Function Deployment (QFD) was used to successfully convert customer needs into engineering requirements to ensure quality is built into the product that the customer needs. Based on the data the requirements were cascaded to the subsystem level to understand and determine the attributes of the vehicle system. Trade-Offs were identified for the specified requirements to be achieved. Decision must be made to consider the trade-off or balance the performance of these involved systems and entities to minimize them.

|  |  |

|---|---|---|

|  |  |

|

Requirement Cascade Table

The table for requirements can be accessed here.

Conceptual Design, Program Timing Plan and Financial Plan Development

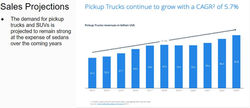

As we proceed to the next phase we look at implementing the trade-offs and changes to review the benchmarking table, create vehicle packaging with set dimensions, establish major milestones, forecast future sales, breakdown the vehicle manufacturing costs, use V model to propose estimate time required for each milestone in the program such as concept design, detail design, design sign-off, etc until Job#1 and beyond where the program is disposed. The cumulative cash flow is plotted to show the break even and forecast the revenue keeping in mind the estimated cost of the new vehicle.

|  |  |

|---|---|---|

|  |  |

|  |  |

|  |  |

V-Model, Cost and Sales Projection sheets

View the V model, Cost and Budget plan below.

Major challenges and future aspects

Why will it sell?

From the sales projections, the expected break even occurs after 11 months from Job#1 which is on February, 2025.

The product will be introduced in the global market to accommodate a wider customer platform. Due to this, over the entire product life cycle the expected revenue is about $37 Billion.

Challenges:

Fuel economy and emission compliance to meet existing and future standards due to unclear CAFE requirements. Also due to global expansion meeting foreign regulations was also a major challenge.

Expanding markets and continuous upgrades from competitors also pose a problem and makes it necessary for us to re-evaluate our design and update our program continuously.

Risks such as inflation in global markets, economic crisis or a natural disaster also makes it difficult in estimating the exact sales of the vehicle.

Future Aspects:

Concentrate on the implementation of fully electric model.

Improving the quality by optimizing the cost.

International branding

Expanding the dealer network

Technology Plan and Vehicle Validation Plan Development

This section details the plans for technology updates to the MY2025 Jeep Gladiator along with a series of validation plans to test the vehicle to evaluate the expected market response through expert and customer evaluations and survey in controlled and actual drive condition.

Powertrain Technology Plan

Implementations proposed:

The major changes in powertrain technology are the inclusion of PHEV drivetrain that consist of a 100kW motor powered by 20kWh battery pack.

A downsized engine option with 2.4l turbocharged I4 engine is provided.

Spark charged compression ignition gasoline engine considered.

Challenges:

High development costs

Meeting CAFE and EPA standards

Risk of knocking due to high air intake temperature

Light-weight material and recyclable material plan

Implementations proposed:

MSC (Material sciences corporation) smart steel body panel to provide 35% reduced weight compared to steel panels.

Increased use of HSS for reduction in weight of BIW

Corning gorilla glass windshield

Challenges:

Trade-off between cost and weight reduction for better fuel efficiency

Safety technology plan

Implementations proposed:

Forward and rear collision warning with automatic braking and V2V connectivity.

Hands free parking

Pro Trailer assist- Dynamic hitch assist

Active cruise control with lane change.

Challenges:

Cost control

Quality and reliability of the sensors

Range of the sensors

Developing the algorithms to improve the precision of the system software.

Parking Assist |  Autonomous Parking |  Trailer Assist |

|---|

Vehicle Cybersecurity and 5G telecommunication

Implementations proposed:

Prevent hackers into the vehicle system. Protect the systems secure from external threats.

Large amount of data needs to be exchanged with server for connected technologies e.g. V2X communication which will require a 5G connection

Challenges:

Increase in cost

Complex software that needs to be regularly updated

Need for reliable network coverage

Compatibility with other sensors and ECUs.

Electrical Systems Architecture

Implementations proposed:

Switching to CAN-FD protocol allows faster data transmission which will be needed for new active safety features, autonomous driving features and other new features are added.

800V architecture for faster charging.

Challenges:

Cost control

Structure layout design of the ECUs

Compatibility between sensors and ECUs.

Developing the architecture to improve the total capacity of the vehicle internal communication.

Other unique features

Implementations proposed:

Interior/Exterior customization and personalization option

Trailer stability and steering assist

Smart summon

Dual-action tailgate

Challenges:

Increase complexity in service and maintenance

Leads to increased costs

Removable doors and roof mechanisms increases manufacturing complexity

Need for storage of the detached part.

Validation Plan

The validation plan is used to test the vehicle to evaluate the expected market response through expert and customer evaluations and survey in controlled and actual drive condition.

Major Validations to be performed:

Performance

Battery safety

Cargo space

Validation Plan for Performance

Field Test:

Three prototypes, equipped with 2.4l I-4 turbocharged engine, 3.6l V6 engine and PHEV powertrain are tested on proving grounds by drive test engineers.

Feedback from the drive test engineers is recorded to verify whether the performance attributes meet the engineering requirements and can satisfy the customer needs.

Prototypes are also are compared with the 2024 models of benchmarked vehicles such as Toyota Tacoma, Chevrolet Colorado, Ford Ranger.

Mules with the three powertrains are tested in normal traffic conditions with respect to their acceleration, deceleration and braking performance.

Fuel economy can also be validated with the help of mules for different prototypes.

Customer Evaluation:

Around 50 subjects invited to market research clinics across different cities.

Subjects drive the vehicle around predetermined route with and without trailer.

The route contains varying traffic conditions and on and off-road driving.

Subjects asked to drive while in different modes - with gasoline engine engaged and in electric only mode.

Subjects may also be asked to drive benchmarked vehicles after removing badges and logos.

Finally, answer a set of questionnaire related to performance.

Camouflaged Mule |  Drive evaluation |

|---|

Performance Validation Plan

(Sample Questionnaire)

Validation Plan for Battery safety

Validate that the vehicle meets FMVSS 305 requirements

Vehicle is crash tested by IIHS

During standard front/rear/side impact and rollover crash tests, battery parameters additionally monitored.

IIHS 305 box is attached in the vehicle to monitor battery temperature and disconnection of battery from drive circuit, post-crash.

Crash Test |  IIHS 305 box |

|---|

Validation Plan for Cargo space

Lab Test:

Cargo space measured in litres using coordinate measuring machine.

Cargo volume benchmarked against newest model from competitors.

Customer Evaluation:

Subjects asked to load/unload items in the bed.

Load vehicles such as bicycles, motorcycles, ATVs and use the straps provided to restrain them.

Asked to load cargo such as hardware items bought from stores such as Home Depot and validate cargo volume.

Finally, asked set of questionnaire related to ease of using bed and storage space.

Post Evaluation Survey Analysis Report

Report: Technology and Validation Plan

Attached report contains a detailed record of all the Technology and Validation plans for the MY2025 Jeep Gladiator. This report also documents the testing procedure, type of survey used, sample survey forms, questionnaires and illustrations of the results that were obtained.

Discussion and Conclusion

All the major changes, tests and plans for the MY2025 Jeep Gladiator that are described and presented above are to be implemented and performed for customer satisfaction and to achieve good sales in the intended target market against competitors in the same segment. However the implementation of these technologies and conducting the validation tests come with trade-offs such as trade-off between cost and weight, Cyber security vulnerability, Achieving best in class battery range, etc.

In order for the developed vehicle program to progress without any delays and to ensure the implementation of all the proposed technology and validation test procedures, the proposed plans should be executed on schedule without delays and regular checks should be conducted to evaluate the progress and any required minor changes should be incorporated during the initial phase of the program. This will allow for a systematic and structured development of the MY2025 Jeep Gladiator.

To conclude, the major focus of the MY2025 Jeep Gladiator vehicle program is to concentrate on the implementation of complete electric models, improving quality by optimizing the cost, international branding and expanding the dealer networks across the globe.