End-to-End High/Low voltage Design | Quality | Scaled Manufacturing

Systems Design Engineer- Electric Drive Module (EDM)

Stellantis North America, Michigan

About Stellantis

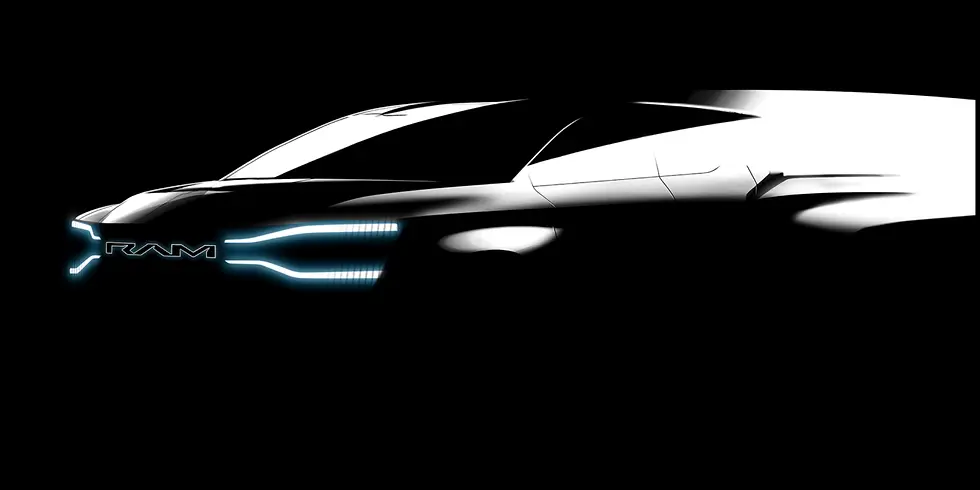

Stellantis is a constellation of 14 iconic automotive brands and two mobility arms that are about more than transportation: they’re about moving people and making connections.

Leading the charge in electrification and software development, with cutting-edge technologies at the heart of products and services.

Fully committed to customers and backed by partners who are leaders in their industries, aiming to develop, engineer, manufacture, and scale the best breakthroughs in all facets of sustainable mobility from autonomous, connected, electrified, shared, and pre-owned vehicles to micro-mobility, commercial vehicles, and even electric aircraft.

With a community of 165 nationalities, industrial operations in more than 30 countries, and customers in more than 130 markets, Stellantis is among the most diverse companies in the world, able to unite people and ideas across borders and cultures. Stellantis's passionate, talented, and diverse teams support our iconic brands in providing freedom of mobility tailored to every need.

Responsibilities

August 2020 - July 2024 (4 years)

-

Lead components project kickoff discussions – deliverables, timing, scope, milestones

-

Requirements negotiations/trade-off analysis with Propulsion System Chief Engineer

-

Support the component DREs in meeting the program objectives in terms of timing, performance, efficiency, validation, system integration, quality, reliability, manufacturing, serviceability, etc.

-

Lead the development of component-focused electrical architecture according to the vehicle architecture

-

Lead the development of component-focused Mechanical integration according to the vehicle's functional objectives

-

Lead the coordination for hardware clean point with software teams (at STLA and/or component supplier) to ensure software deliverables for the given milestone are met on time

-

Coordination and implementation with the cross-functional teams and component COEs for component-related issue closure and risk management

-

Support the generation of component status decks for PR, MR milestones to support technical decisions related to the assigned components

-

Alignment of IAA, CN, DFMEA, and DVPR documents

-

Communication to senior leadership

-

Support cost and timing for the bulletin and study process

-

Support cost reduction activities for components

-

Support the technical reviews/evaluations and technical specification sign-offs (Critical Design Reviews); ensure best practices and lessons learned are applied

Components worked on and supplier collaboration

High Voltage Inverters | 400-800V | 200-350kW |  HV and LV connectors | ICD | IP ratings | Terminal configurations for modular application |  Modularization (E-Drive system) | Inverter-Motor-Reducer integration | System level product ownership |

|---|---|---|

E-Axle integration | Heavy duty application | Validation | Torque vs Speed Trade-off |  Supplier |  Supplier |

supplier |  Supplier |  Supplier |

Supplier |

Key Achievements

-

Reduced inverter manufacturing takt time by 15% by resolving key stoppage issues from the pick and place machine and EOL fault rate .

-

Drove R95C90 reliability through validation of E-Drive modules

-

Solved issues and critical failures within 70 days to prevent program milestone delays

-

Negotiated ~$4-piece price savings over 200k volume for a safety change during the beta development phase

-

Prevented supply chain shortage on Silicon IGBT through second sourcing and driving quick development cycles through seed design

-

Patented embedded technology (Integrated heart rate sensor to ADAS interface) through Stellantis start-up initiative.

Competencies

-

Engineering Tools: NX Teamcenter, WebCN, ICDs, CATIA, PSIM, GT-Suite, ThinkCell, Power BI, Jira, and MS Office package.

-

Industry proficient in Network topology, Schematics, CAN Architecture, GD&T, DFMEA, DVP&R, DFM, EBOM, 8D, Ingress protection, APQP

-

Industry standards: ISO/SAE 21434 (SAE Level I & II cert), ISO 26262, ISO 14644, FMVSS 305a

Takeaways...

A collaborative opportunity to work with diverse cross-functional teams, suppliers, and components across the globe while honing technical and managerial skills.

Lessons and bonds forged through successes and failures, moments of fun while solving them, are core memories that I carry forward through my career progression.